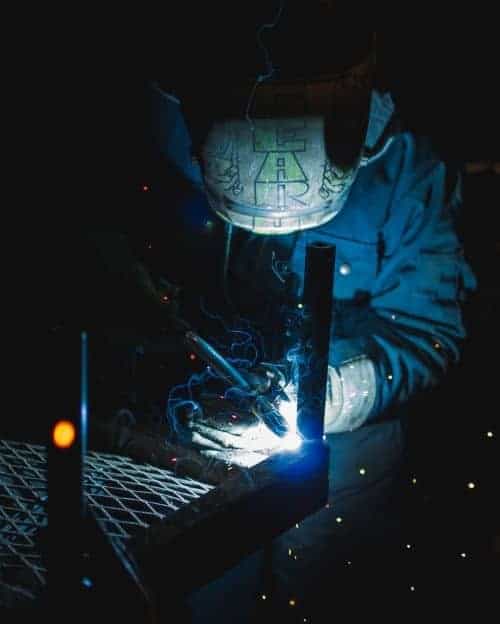

Welding is a really useful skill, and it’s also a good job. You can enter the workforce quickly with minimal studying and make pretty decent money while doing it. Anyone that likes making stuff and can work hard should definitely consider a career in welding.

What does a welder do? A welder uses heat to fuse metals together. This can be used for joining, fabricating, and repairing metal components and structures. There are several different kinds of welding, and welders generally specialize in one or more of these kinds.

In this article we’ll go over what the work is like, what are the kinds of welding, and what to expect for pay. Hopefully this will help you decide if this is a career you’d be interested in pursuing.

Use the table of contents if there’s any particular information that you’re looking for.

Table of Contents

What Does a Welder Do?

Depending on the kind of welding, welders do a pretty wide variety of work. A large percentage of welders in the US are working in the manufacturing industry, although there are lots of other positions available.

Welders heat up metal until it melts in order to join pieces together or to build up worn-out areas for repair. Here are some examples of common things for welders to work on:

- Structural

- Pipe

- Automotive

- Maintenance and repair

- Consumer goods

- Underwater

- Agricultural

- Industrial

Usually working as a welder consists of measuring, cutting, and joining metal together. Sometimes the job doesn’t take too much planning and things are mostly done for you, like in a high-production manufacturing job. Other times it takes a lot of planning, like with repair or prototyping work.

Here are some skills that are commonly expected of welders, in addition to being able to weld:

- Blueprint reading

- Basic math and trigonometry

- Weld inspections

- Familiarity with different materials

- Ability to maintain equipment

Ok, that’s the rough overview. Now for the real question:

How Much Does Welding Pay?

Here’s a breakdown of info I scraped from the US Department of Labor’s Bureau of Labor Statistics. Seems legit, especially if they’re using fancy words like “bureau”.

Ok so the median wage across the country for welders is roughly $40k/year. This means that half the welders make more, half make less. That works out to about $20/hourish.

The lowest 10% (which would be less skilled or apprentice workers) made about $27k/year, whereas the top 10% made over $60k/year. Really, this is a pretty solid job considering how easy it is to get into.

The other thing with welding is that there’s a lot of opportunity for overtime. At a lot of jobs, this is actually a requirement. This is a good indication of the demand for welders. If you’re making $20/hour, overtime will bump that up to $30/hour for the extra time you’re working. That can be a pretty nice boost to your paycheck.

Later on in this article I’ll go over some more information, like which states pay the highest and where the most work is.

What’s the Work Environment Like?

For a lot of people, this is the turnoff. It can be pretty filthy work, and it ain’t easy, either. For others, though, this is all part of the fun.

Overall, there’s a lot of variation in the work environment for welders. It really depends on what you do and what company you work for.

Since that answer is super unhelpful, here are a few examples of what you might run into.

Working for a manufacturing company might mean that you’re standing on your feet all day in an industrial plant. Some shops are nicer than others. You might have a clean, well ventilated shop, or you might work in a dungeon. Always ask for a tour before accepting a position.

According to the US Bureau of Labor Statistics, over 60% of welders work in manufacturing.

Working as a pipefitter will probably mean that you’re working onsite at a lot of different locations which change as projects come and go. As with all construction sites, there will likely be a lot of extra safety requirements and gear that will be a part of the job. You might also be involved with renovating and upgrading existing systems.

TIG welding can be extremely clean. This is a type of welding that requires a lot of skill, but it’s a pretty comfy job once you’ve got the hang of it. I’ve done it before in a shirt and tie and came out pristine.

Working for a mobile welding company can be extremely varied. One day you might be fabricating hand railings or ladders, the next you might be on a construction site. Typically, a lot of your time will be spent outdoors.

At any rate, you could have a pretty fresh outside job, or you could work in the bowels of a soon-to-be condemned building.

Is Welding a Dangerous Career?

Actually, the answer is yes. It totally can be.

Statistically speaking, welders have one of the highest rates of reported injuries and illnesses. Here’s an overview of the likely hazards that you’ll face as a welder:

- Welding uses heat, so you’ll be working with very hot pieces of metal – it’s easy to get burned.

- Intense light from welding can result in something known as “welder’s flash” – it’ll feel like there’s sand in your eyes for a few days. It ain’t fun.

- You could be working with some pretty heavy equipment, so there’s a risk of injury via squashing.

- There can be some pretty nasty chemicals released from welding, especially if you’re working around paint or metal coatings.

- Risk of physical injury from welding in awkward positions.

Overall, though, this is pretty well all counteracted by simply following proper safety procedures and using personal protective equipment (PPE). Here are the examples:

- Removing paint or coatings prior to welding.

- Wearing safety glasses, a welding helmet, hearing protection, heat-resistant clothing, welding gloves, steel-toed shoes…. you get the point.

- Following safety protocols. For example, shouting something like “eyes” when you’re around people before you start welding. This alert them and give them a chance to look away.

I’ve worked in shops for a while, and I’ve been in charge of safety for a few years. From what I’ve seen, pretty well any major accident (excluding dumb things like cutting your thumb on something sharp and pokey) has happened because someone wasn’t following the safety rules.

Here’s the bottom line: Be safety-conscious, and you really don’t have to be too worried.

However, if the thought of these potential hazards completely terrify you, then maybe being a welder isn’t for you. You will be exposed to risks. There are other jobs out there that offer more of a protective bubble for your 9-5.

How to Become a Welder

Generally the only initial requirement is to have a high school diploma or a GED. However, training from there is a really smart idea. Lots of companies require it.

To be clear, you do not need to be certified to work as a welder. Lots of people will tell you that it’s mandatory. It’s not. However, not being certified will exclude you from some jobs.

Here’s a quick overview of your options.

Certification Programs

This is the most straightforward way of getting into welding. Take course, get certified, get job.

Most courses for welding will take about 6 monthsish to complete. Provided you pass, of course.

To sign up, check out local technical colleges. Some high schools might even offer programs that will let you earn a certificate.

Apprenticeships

This can be a great option if it’s available in your area. Just ask around for the welder’s unions and inquire if there are any openings. They’ll outline the steps you need to take to get on board.

This will take a little longer, but you’ll be making money while you’re learning and overall it’s a cheaper route.

On-The-Job Training

If you get a good reputation within a good company, they might decide to train you as a welder. This is by no means a guaranteed way of becoming a welder, though. That said, if you get the opportunity, you might want to jump on it.

At the end of the day, you need to see what’s required in your area. If companies are only hiring certified welders, then it doesn’t really matter if the government requires certification or not.

The surest way to get a job as a welder is definitely to just take a course and get certified. The other options are most so opportunities that might pop up.

One thing to keep in mind is that welding is a very skills-based career. You’ll need to keep welding to maintain your skills, and you’ll need to get re-tested every so often to maintain your certification.

If you want to take a closer look into the actual certification for welding, either check in at a local school or look at the certifying body for your area. For the States, this is the American Welding Society. For Canada, this is the Canadian Welding Bureau.

How Hard is it to Get a Job as a Welder?

Not even slightly hard. There are tons of jobs out there.

Of course, there will always be slow periods. That’s what you’ll see with pretty much anything. For example, when the price of oil goes down, a bunch of welders get laid off, then they find jobs with other companies. The overall result is that the entire job market gets a little competitive for a while.

That’s normal, and it happens all the time for lots of trades.

Ok, so in terms of official stats, the US department of labor says that there’s an overall expected increase of 6% in terms of job openings, which is pretty standard among the trades.

That doesn’t really paint a complete picture, though. See, the real benefit to becoming a welder is that there will be a lot of openings in the future.

A lot of the blue collar workforce is retiring over the next few years. A lot of statistics don’t factor this in when they give you the “outlook projections” and whatnot. The point is, if you become a welder, you should have no major problems finding work.

There are a lot of university programs that can’t say the same thing.

Which is the Best State for Working as a Welder?

This is kind of interesting. Once you get your certification and some experience under your belt, is it worth moving to a welding hotspot? Here are a few of the highlights that’ll save you a boring read through some pretty dry charts.

The highest paying state for welders is Alaska. The hourly mean wage there is over $30/hour. Remember, that means that half the welders make more, half make less.

The next highest paying areas are the District of Columbia ($29), Wyoming ($29), Hawaii ($28), and North Dakota ($26).

The state with the highest amount of welding jobs per capita is Louisiana ($24). From there, the top states are South Dakota ($18), Wyoming ($29), Oklahoma ($21) and Mississippi ($21).

A lot of guys say that Texas is a hotspot for welding, and this is partially true. There are a ton of welding jobs there, more than any other state. However, there are also a ton of people living there. So the ratio per capita is actually pretty average.

At any rate, you’ll be OK wherever. Those are some especially good states to be in if you’re a welder, but there really are jobs everywhere.

How Can I Make Great Money as a Welder?

There are a few areas of specialization that will make you, on average, much more than your typical corner store welding gig. Here’s a partial list of some specialties to keep your eye on if you’re wanting to make solid money.

Pipeline welding is one of the consistent high payers. Natural gas distribution has a mean annual salary of over $70k. Pipeline oil transportation has a mean of about $65k. If you’re better than average, you can really cash in.

This is a job that’ll have you outside pretty well all the time, regardless of weather. Sometimes it’s great, sometimes it’s miserable.

Underwater welding is one that often comes up in discussion. It is one of the higher paying fields, with a mean salary of a bit over $57k. This is something you gotta take with a grain of salt, though. You need to be a professional diver as well as a certified welder, and this is a really dangerous job.

One of the most accessible job descriptions to shoot for, regardless of where you live, is a welding supervisor. You’ll need to apply yourself to achieve this, but the mean salary is about $62k. That really ain’t bad at all.

What Kinds of Welding Are There?

There are a few acronyms and terms that might sound entirely confusing if you’re not familiar with them. Here’s a quick overview of some of the different kinds of welding, along with an basic explanation.

Arc Welding

A fancier name for this is Shielded Metal Arc Welding, or SMAW. The less fancy name is “stick welding”.

This kind of welding is messy and smokey. You’ll have a metal stick that you clamp into a holder. The metal is covered in a thick coating, which releases inert gas when it’s burned. This is what protects the molten metal from oxygen.

This is a super cheap way to weld. Consumable costs are low, and the machines are a dime a dozen. The machine is powered by electricity. This is a really common way to weld steel, especially with construction welding.

MIG Welding

MIG stands for Metal Inert Gas. Since people love making things more complicated than they need to be, it’s also referred to as GMAW, or Gas Metal Arc Welding.

Instead of a stick of metal being melted, a wire is used instead. Pull the trigger and the machine will automatically feed the wire through the welding gun, making everything sparky and fused-y. There’s also a bottle of inert gas that’s used to shield the molten metal.

MIG uses electricity to melt the metal, and it’s most commonly used for welding steel. However, it can also be used for stainless and aluminum.

TIG Welding

This one is my personal favorite, but all kinds of welding have their place.

TIG stands for Tungsten Inert Gas, and it’s also known as Gas Tungsten Arc Welding, or GTAW.

This one’s a little different. The electrode (the part where the electricity comes through) doesn’t melt. Instead, it just melts the metal into a little puddle. Extra weld material is added by a filler rod, which you’ll hold in your other hand.

And, because that’s not complicated enough, you also control the voltage with a foot pedal. So basically you’re using both hands and one foot to do your job.

This welding is super clean, though, and it produces really nice looking welds. It’s common for metals like aluminum and stainless steel, and shops that are exclusive for TIG welding are usually really nice.

Oxy-Acetylene

This one is fun, too. It uses a flaming torch that’s powered by gas. In this case, it’s a mix of oxygen and acetylene.

It’s kinda similar to TIG welding in that the torch is used to melt the metal, and a filler rod is used to thicken up the weld. This is a great way to weld steel, and it’s also easier to weld very thin sheets of metal. I’ve used this kind of welding a lot to do autobody repair on my trucks.

Related Questions

Can I get a job as a welder with no experience?

You don’t need to have experience to start as a welder. Ideally, though, you’ll pick up your AWS certification to get some kind of hiring appeal.

If you’ve got zero experience and zero qualifications, try using your own connections to get your foot in the door. You’ll obviously not be making a ton of money if you’re starting from square one, but you can always renegotiate once you have some experience. Or just accept a position at a new company.

How long does it take to become a welder?

Generally most programs will take 6-9 months to complete. Apprenticeships will usually take you longer. Overall, you can get a job really quickly.

Like pretty well everything, the pay will start off low and steadily increase as you gain more skill and experience. This is especially the case if you try and qualifying for different kinds of welding. A few welding tickets in your pocket is a good sign that you apply yourself to your work and want to improve.