This is a question that seems to have a dozen different answers and is constantly argued over. As with everything debatable, the answer is more than just a simple yes or no.

Is CNC programming hard to learn? Very basic CNC programming is easy to learn, provided that you understand basic math and have a grasp of how machining works. This can usually be learned within a few days. Intermediate programming skills can be learned within a year and advanced CNC programming can take several years to learn.

So it’s just like everything else that seems to merit a straightforward answer: it depends.

In this post, I’ll go over what this means. What you can do with basic CNC programming, what intermediate and advanced means, and how you can go about learning how to program CNC machines in the most painless way possible.

First, though, let’s go over the two main approaches to CNC programming; how they’re different, what they’re good for, and which one you should learn.

Table of Contents

Manual Programming vs CAM vs Conversational

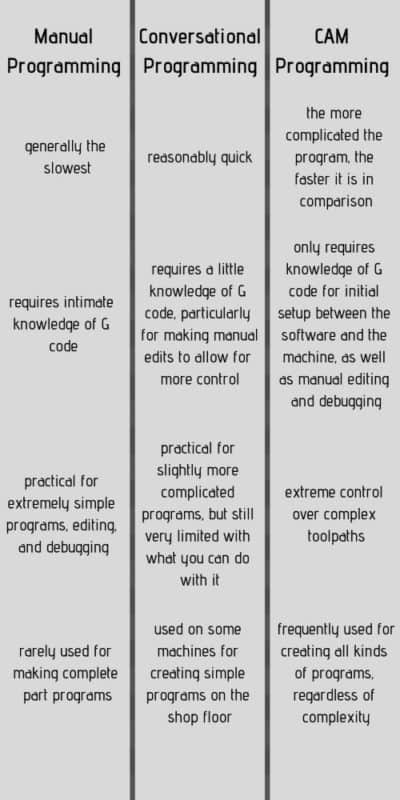

If you’re entering the CNC programming arena for the first time, you really need to understand the differences between these three approaches.

Manual programming is when you are manually writing out the codes. You get an extraordinary amount of control over absolutely everything the machine does, but it’s very time consuming and it’s limited to simpler functions.

CAM stands for Computer Aided Manufacturing, and it’s when you use a computer program to work with a model of the part you’re making. You describe the toolpaths you want, along with additional machining parameters, and the program will generate the actual G-code for you. This is by far the most common way to program CNC machines, and it really excels in both speed and handling complexity.

Conversational programming usually done right at the machine, and it works on a bit of a gradient. The true “conversational” programming will send the instructions directly to the machine. You basically select an operation from a list, plug in the required information, and then the machine executes it.

The “not exactly conversational” programming is most commonly called “quick code” or something along the same lines. The interface is basically the same thing, but instead of simply running the program from a conversational format, you’ll export the program into G code. From there, you can manually edit the code or just run it. It gives you a little extra control over what’s going on.

It’s essentially a hybrid of conversational and manual G code programming.

Here are the fundamental differences:

Which Kind of Programming Should I Learn?

That comparison of the three approaches might make it seem that manual programming is obsolete. Is it?

Yes and no.

It’s extremely practical to understand. If you don’t know the how to code manually, you’ll have a miserable time trying to debug programs and solve problems as they come up. And if you get a new machine that doesn’t communicate perfectly with your CAM system, you could have long-term problems if you don’t understand the code that’s running between the two.

Most machines will also have some sort of quick code function, too. In my experience, it’s pretty rare to find a machine that outputs quick code that needs zero editing. It’s usually just a means of quickly putting together programs (maybe that’s why they call it “quick code”?) for the machinist that’s comfortable with manual programming. You skim through the output code, make any tweaks that are needed, then run through the program.

So here’s my bottom line recommendation:

Learn manual programming first. Get a good grasp of how programs work, what the different codes mean, and what you have to watch out for so that you’re not blindly feeding incorrect programs to the machine.

Once you’ve got a handle on that, then move on to learning a CAM system. There are a ton of different programs out there, all with their own pros and cons. But at the end of the day, once you’ve learned one CAM system, picking up another one is generally just a matter of finding where the buttons are and maybe learning a few different terms. It doesn’t take long once you understand the core concepts.

A caveat: If you’re using a CNC router to cut basic profiles, there’s generally no real need to learn manual programming (although it never hurts). Those programs are so simple and straightforward that it’d be a really rare situation for you to need to edit the G-code.

Stages of Difficulty for CNC Programming

Ok, so earlier I said that the difficulty of CNC programming is dependent on how complicated you can get. Here is a range of what you might come across in terms of jobs and the degree of difficulty for programming.

Mill Programming

The most basic programming that you’ll be doing for milling is what’s called 2-1/2 axis machining.

Here’s what that means:

The machines move in 3 axes, but with 2-1/2 axis machining, you’re not using all three axes simultaneously. You’re generally cutting 2D profiles and simply moving the cutter up and down to get to the required cutting depth for the operation.

Another common thing to do with this type of machining is using something called a canned cycle. This is basically a function that will describe a series of motions by defining a values. On a mill, this is most commonly used for holemaking operations. Basically, you give the machine coordinates and parameters, and then it will know any series of motion that you’d like the machine to follow in order to make that hole.

Examples include spot drilling, peck drilling, and tapping holes.

For this kind of programming, you can generally use all three approaches – manual, conversational, or CAM.

A step up from this is 3 axis machining, also known as contouring. This is where all 3 axes of the mill are moving at the same time. This is used for machining things like 3D molds or patterns, along with a slew of other things.

The reason that this is more complicated is that the geometry is more complex, and there’s basically just more going on. This is where the complexity of the program separates the approaches; manual and conversational are no longer practical, and CAM programming is pretty well a requirement.

3+1 or 3+2 axis machining are the next step up on the complexity ladder. The +1 or +2 refer to rotational axes, which are used to index the part (as opposed to all moving simultaneously during a toolpath). Again, just more going on. That said, a really simple program for a 3+1 part can definitely be done manually. For example, if you’re using an indexer or rotary table to drill crossholes in a tube, this is a really straightforward program to do manually.

However, these jobs are generally a bit more complicated and are best off done with a CAM system, especially if you’re doing any sort of contouring.

True 5 axis machining is just about the most complicated thing that you’re going to do on a mill. Aside from these machines being more expensive, the programming is a fair bit more intense. It’s not uncommon for a complex 5-axis program to have over a million lines of code. Obviously, you’re not going to want to do this by hand. CAM required.

Lathe Programming

The standard lathes have only 2 axes, and they’re actually pretty easy to program manually. If it’s a short and simple program, a lot of guys choose to punch in a program by hand simply because it’s faster than walking over to their computer and sitting down.

So 2 axis turning is the most straightforward type of programming, and it’s your call how you want to handle it. Generally, the longer the program, the more it makes sense to use CAM.

3 axis programming for a lathe is usually used for lathes with live tools. This means that there are milling or drilling tools that rotate in the turret. You can use this for things like drilling crossholes or milling flats or hexes on a shaft in a single setup. It’s nothing too crazy to program by hand, but most guys would prefer to program using a CAM system.

Multifunction machines are beasts. These are the love children of mills and lathes. You might have a mill that can rotate a table at high RPM and do turning. Or you might have a lathe with a big milling head mounted over the chucks.

For these, part complexity generally determines the programming approach. Usually, you’ll use quick code of conversational for the simple stuff and CAM for the more complicated stuff. Or just use CAM for everything, because you might be more comfortable with it.

Is Manual Programming Worthwhile?

Absolutely. It’s the foundation of CNC programming. Even if you don’t use it on a regular basis, it allows you to make edits at the machine instead of running back and forth between the machine and your computer trying to figure out how to fix something.

Think of it as a first-grader learning the concepts of addition and subtraction with blocks or candy instead of just being handed a calculator. You’ll understand what’s going on, what the machine needs to be able to execute commands, and you’ll be able to rely on your own skills instead of needing to call people for help if something doesn’t go perfectly (which happens pretty often in a machine shop).

If you’re looking for some good courses to learn CNC programming manually, I’d really recommend checking out my resource page on this. It also gives some pointers on how to get started with CAM programming. You can find this information here. This is, in my opinion, the most painless route to getting started with CNC programming.