Whether you’re a hobbyist or a professional machinist, CNC machines are just plain cool. This is my guide on what to expect when you’re wanting a shiny new machine.

How much does a CNC machine cost?

| Hobbyist-grade CNC router | $1k-3k |

| Professional CNC router | $5k-100k |

| Entry-level (or toolroom) 3-axis vertical machining center | $60k-100k |

| Production 3-axis vertical machining center | $150k-300k |

| Entry-level 5-axis mill | $200k-500k |

| Production 5-axis mill | $500k+ |

| Entry-level (or toolroom) 2-axis lathe | $30k-60k |

| Production 2-axis lathe | $60k-250k |

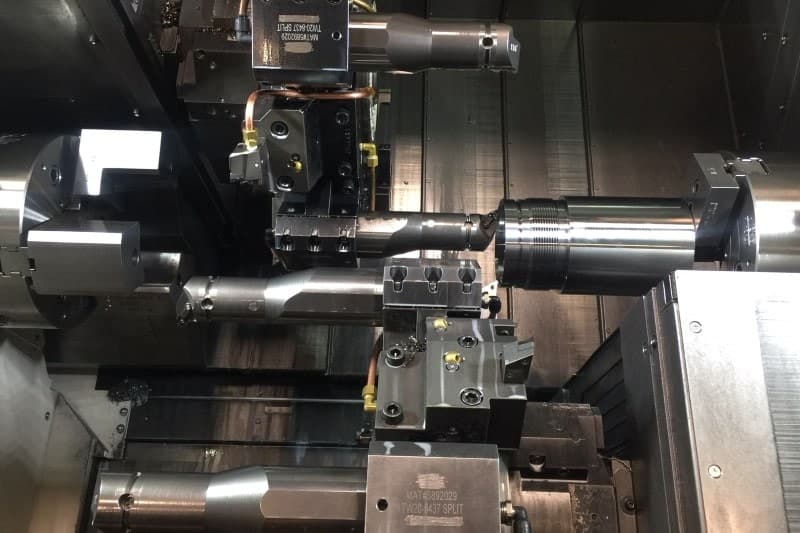

| Multi-axis multi-spindle multi-turret vicious beast of a lathe with robot | $500k+ |

Ok, so those are obviously rough guidelines. There are a ton of factors that go into coming up with a finalprice.

Most CNC dealers are pretty open to negotiation, and you can end up spending a lot on the options. In this post, I’ll give some examples of machines that might fit your needs, what to expect for hidden costs, and give you some tips on how to keep your expenses down.

Table of Contents

Factors that Determine Machine Price

As you probably noticed, those ranges were pretty massive. Here are some of the factors that will influence where you’ll fall within that price range.

- Size of the machine (most commonly measured in X/Y/Z travel)

- Weight of the machine (heavier frame = more rigid machine)

- Speed (RPM, max rapid mode travels, tool change times)

- Power (size of the servo motors, spindle torque)

- Country of manufacture (Korea, China, Taiwan vs Japan, Germany)

- Options (coolant pressure, automatic tool changer, tool/part probing, chip conveyor, pallet pool, robotic part loader, bar feeder, etc)

- Machine configuration (3 axis mill or 2 axis lathe vs 5 axis mill or 9 axis lathe)

Out of all of those factors, size of the machine, configuration, options, and where it’s made will generally make the most difference to the bottom line.

Hobbyist Machines

At the lowest end of the price spectrum, there’s the hobbyist machines. By far the most common type is the CNC router, which is usually used for things like cutting panels or random whatsitmadoits our of plastic, wood, and nonferrous metals.

If you’re just looking for something to play around with in your basement and don’t want to spend any noticeable kind of money, you can get stupidly cheap miniature CNC routers on Amazon that are pretty much only capable of engraving and other really light-duty projects (here’s an example). Generally the instructions require deciphering, but if you’re just looking for a toy, then these can be fun.

If you’re looking for something about half a step up, the Bobs CNC E3 is a machine that will actually let you do some pretty cool stuff in your garage. You can check here to see how it’s priced. Again, though, it’s a hobbyist machine. Don’t expect to start up a machining business with it. At least, not if you want to be able to pay your own bills.

I actually built my own 2’x4′ CNC router and it cost me about $1200 all said and done. That said, I did a fair bit of upgrading from what’s normally offered in that price range so that I could but aluminum with it.

Other options for hobby machines are the ones from Sherline. They sell tiny little manual machines as well as CNC machines complete with a computer to run them. Here’s an example of the lathe and here’s the mill (check link for current pricing). I’ve got the lathe in my basement, and it’s a fun little toy.

The step up from here in what I would still consider to be a hobbyist-grade of machine is what’s produced by Tormach. They advertise their products as “personal CNCs”, but they’re noticeably more capable than the cheap little routers that you can buy online. For their smallest lathes and mills, you’re looking at a price range of around $7k+ and something to the tune of $25k+ for their larger machines.

You can check them out here.

Entry Level CNC Machines

Ok, so let’s say that you’re wanting to do more than tinker in your basement. Entry level CNC machines can do a pretty good job of handling the stuff you’d expect a machine shop to handle. They’re also great for making custom tooling if you’re interested in really pushing your R+D.

Actually, I worked at one composite repair shop where I took care of the tooling. We bought a Haas TM-3P and it worked great for making tools for balancing, molds, and all kinds of other things to help us stay ahead of the competition. One of its main advantages was that we could usually go from concept to result within a day or two, instead of always waiting on a standard 2 week lead time.

Haas is actually a really popular machine tool builder in the US that has a good lineup of entry-level machines. From their toolroom mills and lathes to their small production machines, you can expect to find entry level CNCs starting at about the $30k range.

The nice thing with Haas is that they post all their prices online along with the options. Their “build-and-price” function is pretty handy, or you could just skim through their price list here.

Tip for getting a great deal from Haas: They’re pretty firm on their base prices, but they usually have a bit of wiggle room when they come to options. If you’re wanting to squeeze them for the best deal possible, try to get the rep to throw in as many free options as he can without getting fired.

Production Machines

This is where things get pricey fast. A production machine is a CNC that is working to shave every second off the cycle time. They’re designed to run 24/7 and be pushed to their max.

If you’re thinking of stepping into this arena, you’d better come prepared. You’re best off spending some time with CNC machinists that will understand your needs. You can also visit some manufacturing trade shows to see what’s offered.

There are too many CNC manufacturers to list, but here are a few that you could look at if you want to request a few quotes:

- Matsuura (one of my personal favorites for Japanese mills)

- Nakamura (great Japanese lathes)

- Haas (American, they do have very economical production machines)

- Hurco (known for their easy-to-program controller)

- YCM (Chinese brand that’s easy on the wallet)

- Mazak (old-fashioned muscle)

- Makino (excels more so in the high-end range)

- DMG Mori (very flashy German machines)

- Okuma (good, solid machines for the price)

- Romi (economical Brazilian machines that are great for the price)

- Doosan (huge range of machines)

- Brother (very economical, I like their small but very fast mills)

- Fanuc (probably best known for their small mill/drills)

And there are loads of others, but this will at least give you a starting point on where to look.

The most painful part in all of this is that very few companies like to post their prices online. So you’ll have to call them up, find the local rep, talk to the rep on the phone, let the rep come over and visit you, endure small talk with the rep, talk about hopes, dreams and feelings with the rep, and finally start to get a trickle of information about pricing.

I’ve never been one for small talk.

At any rate, make sure that you get in touch with several different CNC dealers and carefully review what’s being offered before making your decision. Don’t rush it. Besides, the longer you take, the more likely they’ll start lowering their prices to close the sale.

Unexpected Costs of CNC Machines

There is waaaay more to the cost of CNC machines than the actual price of the machines. Here are some of the other things to budget for:

- Tool holders (collets, end mill holders, drill chucks…)

- Cutting tools (end mills, drills, etc…)

- Work holding (clamps, vises, etc)

- Programming software (can be a few hundred a year for a subscription, or a one-time cost of tens of thousands along with annual maintenance fees of a few thousand, or anywhere in between)

- Measuring tools (calipers, micrometers, surface tables and height gages, etc. Take a look here at my absolute basic-of-the-basics machinist’s tool list)

The prices on these will vary wildly based on what you’re needing to do. A common saying is that if you’re wanting to budget for a CNC, then double it to include the tooling. I haven’t always found that to be true, but it does give you an idea of what you might end up with.

If you’re buying an entry or production level machine, here’s what I’d really recommend that you try and do: Get the salesman to throw in some tools.

Usually the machine retailer will also be a distributor for all the tooling as well. To help close a sale, you can generally get them to throw in at least a bit of tooling to help you get started.

Buying Used CNC Equipment

This really deserves to be an article on its own, but there’s a few points worth making.

You can get used CNC equipment significantly cheaper used than new, but you really need to be careful. If a machine has been crashed hard, there might not be a practical way of getting the machine back into its original condition.

Also, production machines often have a life of around 10-15 years, depending on what they’re making and how hard they’re being pushed. Older machines that have been worked hard really can’t keep up with the new machines.

When it comes to determining the condition of a machine, aside from crashes there is one thing that is most important: how well preventative maintenance was done. If you’re buying used, ask to see their preventative maintenance records.

At the end of the day, try and get a good explanation as to why the machine is for sale. If the shop is going out of business, then you might be ok. If it was for a particular job that they no longer have, same deal. If they give you a non-straightforward answer, trust your spidey senses.