Usually, TIG welding is done with pure argon as a shielding gas and an argon-CO2 gas is used for MIG. However, with a massive rise in popularity of multipurpose welders that can do both MIG and TIG, lots of guys want to know if they can keep their setup simple and run a single gas for both.

Can you use argon-CO2 mix for TIG welding? Using this mix for TIG is a really bad idea, since your tungsten electrode will burn out instantly. It is not a suitable gas for TIG welding.

Table of Contents

Different Needs for Different Welds

Just so that you can understand why there is no cost-effective gas that’s good for the MIG/TIG hobbyist, let’s take a quick look at what the gas does for each welding process.

TIG welding uses the gas to keep the tungsten electrode shielded from environmental contamination, like oxygen, nitrogen and hydrogen. It also needs to have a more stable arc, since the electrode needs to be kept at a very controlled distance from the workpiece

Argon helps keep the weld environment completely inert, and it helps to form a very stable, controllable arc.

Carbon dioxide (CO2) is actually an active gas. It causes oxidation, especially around tungsten (which is the electrode in a TIG welder).

MIG welding has different needs. If you use argon with a MIG welder, your welds will be wide and have poor penetration. This is why we add carbon dioxide.

CO2 helps to produce a hotter weld puddle that flows deeper and more quickly. Steel is able to handle controlled atmospheric reactions around the weld puddle, so we don’t run into issues like embrittlement or other problems that other metals would experience.

So, in short, TIG welding needs pure argon to protect the tungsten electrode, and MIG welding works best on a 75%/25% argon/carbon dioxide mix to get good weld penetration and flow.

Helium

Helium is the gas that kind of changes everything. You can use it along with argon for both MIG and TIG welding.

However, it’s expensive and hard to get. Prices always fluctuate, but helium is commonly triple the price of argon and not readily available at most places.

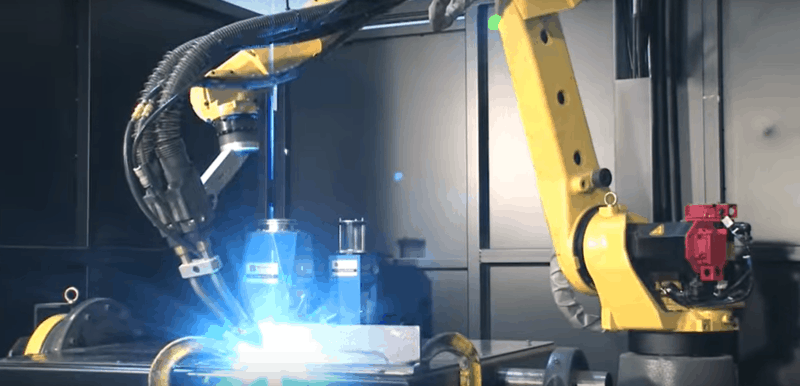

It’s usually just used for large industrial applications, like heavy-duty robotic MIG welders. Helium makes the weld pool hotter, and you can weld much faster by using it. What you pay for the price of helium can be recovered by faster production rates.

So a 75% argon and 25% helium MIG mix can work great for some heavy-duty major industrial outfits, but it’s just not feasible for the small shop or hobbyist.

For TIG welding, it has some pros and cons.

Helium increases heat and decreases stability. Lots of welders run into issues with weld cleanliness when they add helium to their argon, sometimes in the form of a black soot.

Why would you use helium for TIG welding?

If you’re doing thick aluminum plate, the extra heat you get from helium can help you get a lot more welding power from a smaller machine. You can also weld much faster even on lighter stuff.

However, TIG welding with a helium mix is a different animal, and it takes a good amount of practice to not make a mess. Most guys find it significantly easier to just stick to pure argon, especially if they’re welding aluminum 1/4″ or thinner.

The Answer for Multipurpose Machines

For hobbyists that just want a good selection of welding options within arm’s reach, there are a few things that can help you decide where to spend your money.

For example, you might want to just stick to flux-cored arc welding (FCAW), also sometimes called gasless MIG. The wire is considerably more expensive, but you don’t have to use a gas bottle. Expect to pay somewhere around 2-3x for flux core wire vs regular solid wire, but this is often the best choice for hobbyists.

Then you can just buy a small bottle of argon for when you want to TIG. Switching the hoses over to do a quick 10-minute weld can be a pain unless you do some creative plumbing.

If you’re doing welding in your garage less than weekly, I’d definitely consider sticking to FCAW and TIG.

But if you’re using your machine more often than that, it might actually cost you less over the course of a year to just suck it up and buy two different bottles for MIG and TIG.

Either way, there’s no one-size-fits-all solution.

If you’re trying to figure out your options for your own home setup, make sure you read through my guide on welding gear for beginners.